A good source of raw material directly influences the desired end product. Cosmopacks extracts raw material from reliable resources, which have a fine quality base for production. During raw material extraction or production, we ensure that impurities are completely eliminated. Cosmopacks offers Continuous Quality Improvement (CQI) which provides manufacturers with improved and quality delivery. Advanced technological support in raw material preparation detects minor defects in the material, and the defected batch is eliminated to ensure a quality product in the assembly line.

Cosmopacks aims to delight our clients through the highest quality raw material which is approved by

international standards.

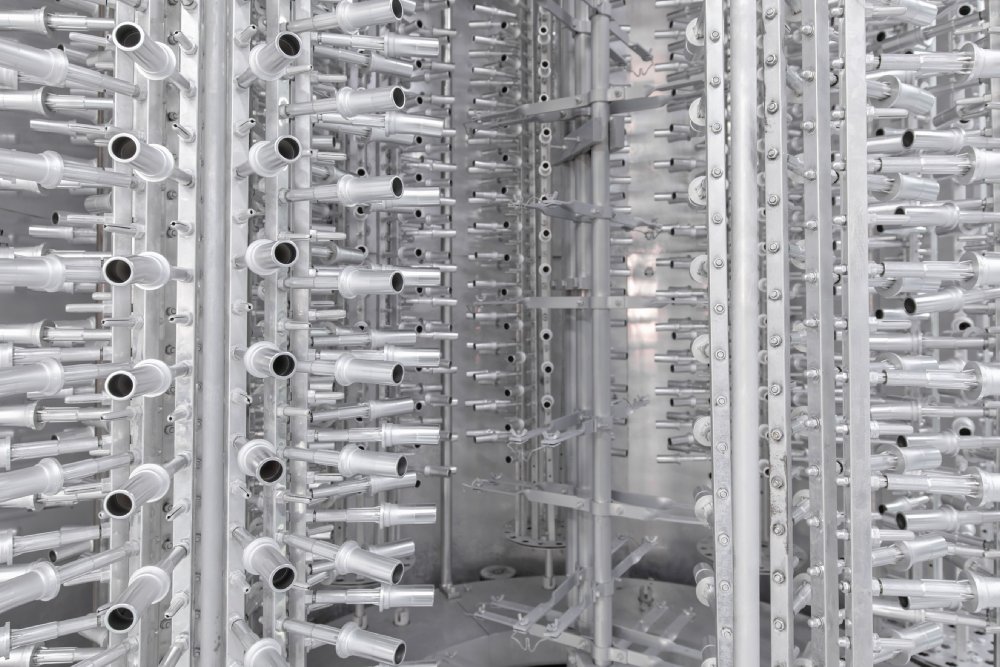

Cosmopacks has revamped the injection molding industry, manufacturing quality products at a large scale. Using injection molding technology, Cosmopacks provides flexible designs, that increase the virtual configuration of products. Injection molding reduces labor and assembly line expenses as the manufacturer receives the perks of cost-effectiveness. In injection molding, usually thermoplastic is used to increase the durability of the utilized parts. Moreover, improper termination, misalignment, and other problems are eliminated. This adds tremendously increases the reliability of the products. As injected molded products do not need fasteners and connectors, the product’s physical strength is relatively increased and weight reduced.

Cosmopacks prides itself on having large-scale injection molding that has the best marks in terms of

cleanliness, consistency, and smoothness

Enhancing the packaging’s surface finish and making them more appealing to your market, we use contemporary processes like vacuum coating and UV coating.

During the manufacturing process, we aim to resolve almost every problem faced by manufacturers through surface treatment. Cosmopacks’ highly dynamic plating process creates a corrosion-resistant surface. Surface treatment awards a glossy finish to products, giving life to dull materials. The unique surface treatment process includes cleaning, polishing, painting, plating, and heat treatment. Cleaning removes dirt, burns, and other foreign substances aiding the longevity of the manufactured products. We prioritize quality and longevity, where materials undergo heat treatments. This improves the resistance of the manufacturable against wear and tear.

To shorten lead time and expedite delivery, we employ the latest automatic screen printing and hot stamping machines that guarantee detailed and consistent prints.

Cosmopacks subjects the products through an intriguing printing process, giving a sensation of luxury and elegance to create the product’s value in the market. Cosmopacks has introduced shimmering gold highlights, glittery silver lettering, and bold copper designs that appeal to the aesthetic sense of all kinds of audiences. We offer hot stamping and vacuum coating to manifest more eye-catching prints. Cosmopacks’ printing process is highly customizable to fit the needs of your customers. Moreover, we’re implementing printing processes with novel technologies to generate high-quality printing results.

Cosmopacks’ Lean Manufacturing helps manufacturers make cost-friendly products, saving time and space for creativity through automated assembly workshops. Precision pumps head assembly machines are included to accelerate the manufacturing stage, increasing the production rate which then makes order fulfillment faster and more consistent. This meets the exceptional demands of manufacturers in the shortest possible time with negligible waste and cost-efficient production.

We believe in delivering the best to manufacturers. Here’s why every product undergoes a standardized inspection process and a strict quality control regimen before dispatch. We’ve prepared an elaborate QC Checklist, including pressure resistance, deform resistance, and leakage resistance checks to ensure the durability of the final product. Manufacturers are welcome to thoroughly inspect products independently or through a third-party inspection agency for their satisfaction. Each production step has a spot check test, while the final inspection includes sizing audits, functional testing, and appearance inspections. Cosmopacks gives heed to such a critical QC process to minimize the possibility of revisions, saving you time and energy.

Sustainability From Start To Finish

Umbrella Industry Zone,Songxia Town, Shangyu City 312300, Zhejiang, China

+1 626 203 5398

info@cosmopacks.com